What Should Buyers Check Before Ordering A Tile Cutter?

A Tile Cutter is one of the most commonly requested tools in tile installation projects, especially where stable, straight cuts are required. For contractors and distributors, the interest usually goes beyond appearance and focuses on how the tool performs during repeated daily use. Manual designs remain popular because they operate without electricity, making them suitable for indoor renovation, retail spaces, and job sites with limited power access.

The basic working principle is simple: the cutting wheel scores the tile surface, and pressure is applied to snap the tile along the line. This straightforward operation helps teams maintain a working rhythm without long setup time.

Why Manual Tile Cutters Remain in Demand

Despite the availability of powered cutting equipment, many professionals still rely on manual options. The main reason is control. A manual Tile Cutter allows installers to adjust pressure and positioning by hand, which is helpful when working with ceramic or porcelain tiles of varying thickness.

Portability is another factor. Carrying a manual cutter between rooms or floors is easier than moving large powered equipment. For distributors, this also means simpler packaging and shipping.

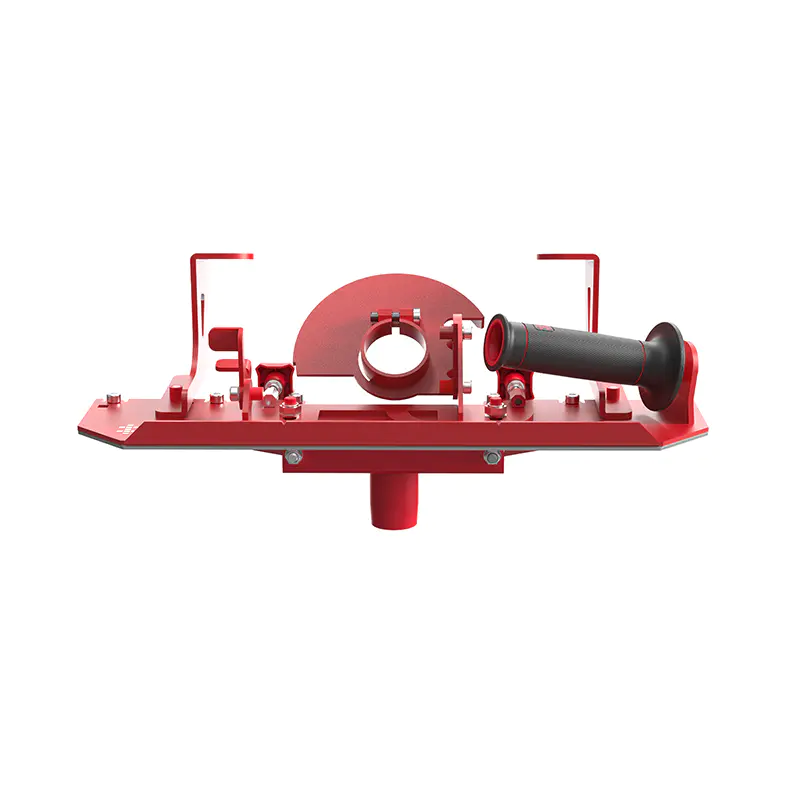

Comparing Iron and Aluminium Base Plate Designs

Buyers often compare base plate materials when sourcing from Tile Cutter Manufacturers. Each structure serves a different working preference.

Iron Base Plate Models

These models offer higher weight and stability. The added mass helps reduce movement during scoring and snapping, which supports consistent cut lines. Iron base plates are commonly chosen for workshops or projects with high daily output.

Aluminium Base Plate Models

Aluminium designs focus on reduced weight and easier transport. They resist corrosion and are easier to clean after repeated use. Installers who frequently move between sites often prefer this structure.

Both options usually include marked measurement scales, helping users align tiles quickly without separate tools.

What Buyers Ask Tile Cutter Manufacturers

When communicating with Tile Cutter Manufacturers, buyers often focus on practical points rather than decorative details. Common topics include cutting wheel material, base flatness, and compatibility with different tile sizes. Tungsten carbide wheels are widely discussed because they support clean scoring with limited surface damage.

Another concern is consistency across production batches. Importers want each Tile Cutter shipment to maintain the same cutting response and structural balance, especially when supplying retailers or contractor networks.

Matching the Tool to B2B Supply Needs

From a sourcing perspective, a Tile Cutter should align with the target customer's working habits. For commercial renovation teams, durability and stability may take priority. For resale markets, weight, packaging size, and ease of demonstration often matter more.

This is why many buyers prefer long-term cooperation with Tile Cutter Manufacturers who can adjust specifications while keeping core performance stable. A clear understanding of how the tool is used in real installation scenarios helps manufacturers and buyers communicate more efficiently and build steady supply relationships.

By focusing on daily usability, base plate structure, and production consistency, a Tile Cutter becomes more than a basic hand tool—it becomes a reliable part of the installation workflow for both professionals and suppliers.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness