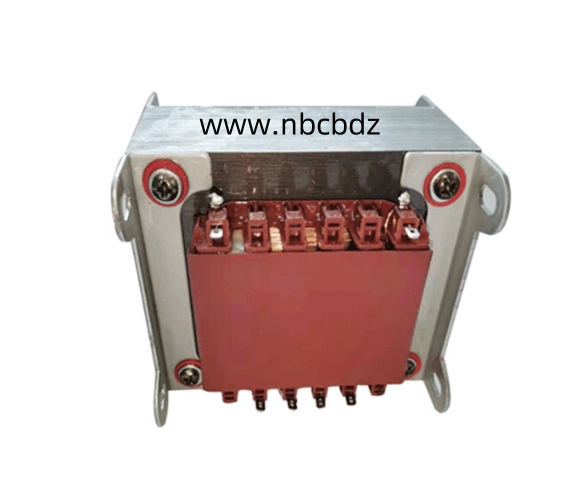

When to consider Nbcbdz Low-frequency Transformer Factory for procurement

Low-frequency Transformer Factory is often part of the supply chain for industries that require reliable electrical components. Buyers looking to source products from such a factory need to understand what matters most before committing to a supplier. Careful preparation can help avoid problems later in the project and ensure smoother cooperation.

The first aspect buyers should evaluate is the technical requirement of their application. Low-frequency transformers are widely used in power distribution, control systems, and industrial machinery. Each of these applications has different demands, from voltage handling to insulation standards. Reviewing specifications early helps ensure that the order will function correctly once it is integrated into the final system.

Another factor to consider is production consistency. A factory should have clear processes for assembly, testing, and quality verification. Buyers often request details about how products are checked before shipment and what records are available. This information is important because it reduces uncertainty about whether the delivered components will perform as expected in real conditions.

Communication also plays a central role. When working with international suppliers, buyers want timely updates on production progress and shipping schedules. Regular contact avoids misunderstandings and helps both sides stay aligned. Nbcbdz emphasizes open communication with its clients, making it easier to resolve technical questions and ensure that projects remain on schedule.

Procurement decisions should not focus solely on pricing. While budget is always a consideration, long-term reliability and service can affect total costs far more than initial numbers. A transformer that fails in operation can cause downtime and replacement expenses. Comparing multiple factors, including durability and support, leads to more sustainable purchasing outcomes.

Another point buyers often look at is the supplier’s ability to adapt to different project environments. Some projects may require custom designs or additional testing stages. Factories with flexible processes can handle these requests more smoothly, reducing delays. Having a discussion about customization options during the early stage of procurement can help buyers avoid surprises later.

Supply chain stability is also crucial. Projects are often delayed not because of technical faults but because of shortages or transport issues. Buyers should ask about raw material sourcing, production capacity, and delivery arrangements. A stable supplier reduces the risks connected with unpredictable market changes.

Before finalizing an order, it is helpful to prepare a checklist of important items. This can include voltage levels, expected delivery date, packaging methods, and any specific certifications required by the project. A well-structured checklist allows both sides to work more efficiently and reduces the chances of missing critical requirements.

Sourcing from the right partner can make a significant difference in the outcome of an industrial or commercial project. By focusing on specifications, quality control, communication, and supply chain stability, buyers can make informed decisions. Nbcbdz provides support in these areas, working with clients to align production with their operational needs. To learn more, visit https://www.nbcbdz.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness