3D Printing Metal Market 2025–2032: Rapid Growth Driven by Industrial Innovation and Advanced Manufacturing

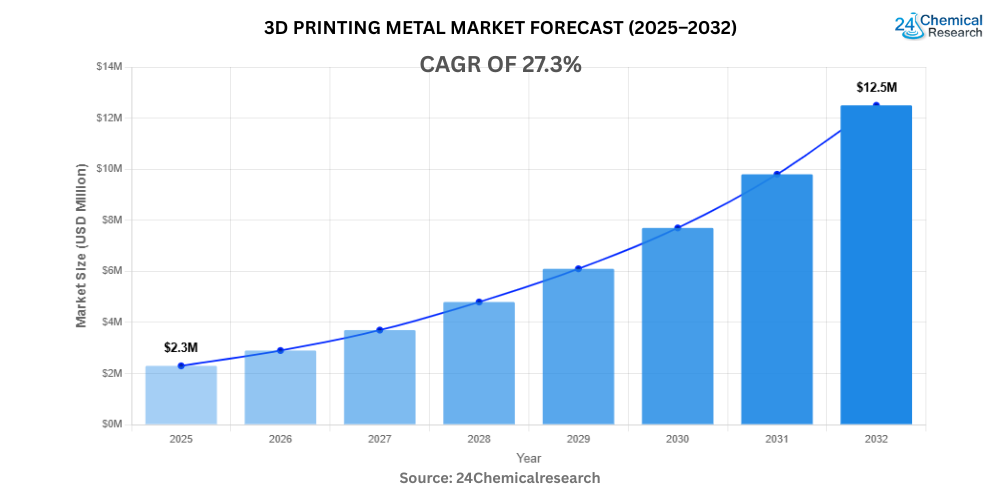

Global 3D printing metal market, valued at USD 2.31 billion in 2024, is projected to rise substantially to USD 21.67 billion by 2032, registering an exceptional CAGR of 27.3%. The surge reflects accelerating adoption of additive manufacturing across aerospace, automotive, healthcare, and industrial sectors, where metal-based 3D printing supports precision design, lightweight structures, and cost-efficient production.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/258957/global-d-printing-metal-market

Market Overview

Metal 3D printing has become a core technology in next-generation manufacturing, offering advantages such as material efficiency, design flexibility, and reduced assembly requirements. The market encompasses materials such as titanium, aluminum, stainless steel, nickel alloys, and specialized high-performance metals. Increasing reliance on prototypes, customized components, and complex geometries is strengthening demand across global industries.

The transition toward digital manufacturing and supply chain optimization contributes significantly to market expansion. Heavy industries are incorporating metal additive manufacturing to shorten production cycles and reduce dependency on conventional machining.

Top Emerging Trends in the 3D Printing Metal Market

Key developments shaping industry progression include:

- Shift toward lightweight metal alloys for aerospace and automotive engineering.

- Rising adoption of metal AM for medical implants, supporting patient-specific prosthetics and surgical instruments.

- Expansion of binder jetting and powder bed fusion technologies, improving print quality and scalability.

- Growing use of additive manufacturing for rapid prototyping, reducing development time and cost.

- Increasing interest in decentralized and on-demand manufacturing, fueling adoption in defense and industrial maintenance.

- Improved metal powder production techniques, enhancing purity, consistency, and printability.

- Integration of AI and simulation tools to optimize part design, minimize waste, and improve structural performance.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/258957/global-d-printing-metal-market

Key Market Drivers

- Strong demand for advanced components in aerospace and defense applications.

- Growth of digital manufacturing ecosystems, enabling mass customization.

- Healthcare sector adoption, driven by custom implants and surgical tools.

- Cost efficiency in materials and processes, as industries shift to additive production.

These factors collectively support the market’s robust CAGR through 2032.

Strategic Developments

Market growth is accompanied by ongoing advancements in production capacity, powder technology, and printer performance. Companies are investing in expanded R&D for new metal formulations and collaborating with industrial end-users to enhance application performance.

Recent industry activities include equipment upgrades, new 3D metal printer introductions, and expansion of powder-based material offerings. These developments align with the sector’s broader goal of achieving high reliability and scalable industrial output.

Technological Advancements

Innovation in metal additive manufacturing is transforming structural design and production reliability. Enhanced laser systems, multi-laser printers, and improved cooling techniques are enabling faster build rates and reduced post-processing requirements.

Automation technologies support efficiency, while advanced simulation tools help predict part performance before production. Collectively, these advancements contribute to sustainability objectives by minimizing material waste and optimizing energy use in manufacturing.

Regional Insights

North America holds a strong position in the market due to early adoption of metal additive technologies and significant investments from aerospace, defense, and medical device manufacturers. The United States, in particular, continues to lead in research, commercialization, and industrial-scale deployment.

Europe demonstrates strong advancements in engineering and metal manufacturing technologies. The region benefits from robust industrial frameworks in Germany, France, and the United Kingdom, where additive manufacturing is integrated into automotive and aerospace supply chains.

Asia-Pacific is experiencing rapid growth, driven by rising industrialization, expanding manufacturing capacity, and government-backed initiatives promoting digital production. Countries such as China, Japan, and South Korea are intensifying their investments in metal-based additive technologies to strengthen their global competitiveness.

Get Full Report Here: https://www.24chemicalresearch.com/reports/258957/global-d-printing-metal-market

Key Companies

Major companies involved in the global 3D printing metal industry include:

- EOS GmbH – Known for high-performance metal additive manufacturing systems.

- SLM Solutions – Specializes in advanced selective laser melting systems.

- Renishaw plc – Offers industrial-grade metal AM equipment and engineering solutions.

- 3D Systems Corporation – Provides metal printers and precision component manufacturing.

- General Electric (GE Additive) – A major innovator in metal additive production technologies.

- Desktop Metal, Inc. – Focuses on scalable binder jetting metal solutions.

- Höganäs AB – A key supplier of high-quality metal powders for additive manufacturing.

These companies maintain competitive positions through technological leadership and partnerships across industrial value chains.

Ready To Make Smarter Decisions? Access Reports Now

· Perfluoroalkoxy Tubing Market

· Electron High Barrier Packaging Films Market

· Synthetic Industrial Wax Market

· Nonwoven Perforated Film Market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

- Plant-level capacity tracking

- Real-time price monitoring

- Techno-economic feasibility studies

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness