Tire Retreading Market Boosted by Rising Adoption in Logistics and Transportation Sectors 2032

Tire Retreading Market: Rising Sustainability Focus & Cost Efficiency Drive USD 8.48 Billion Opportunity by 2032

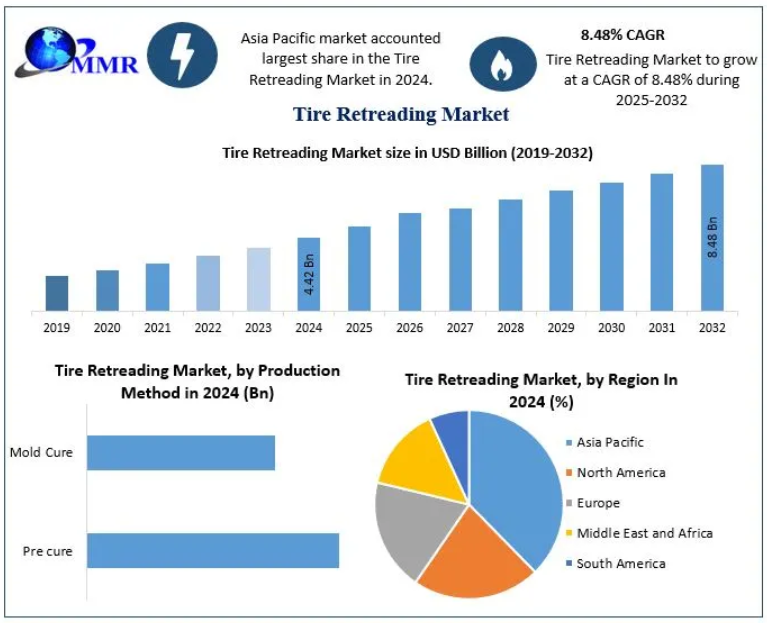

The global Tire Retreading Market, valued at USD 4.42 billion in 2024, is poised for robust expansion, projected to reach USD 8.48 billion by 2032, reflecting an impressive CAGR of 8.48% during the forecast period. As global industries shift decisively toward sustainability, cost optimization, and circular economy solutions, tire retreading has emerged as a pivotal enabler for the future of commercial and passenger mobility.

A Circular Economy Enabler: Market Overview

Tire retreading—where worn tire casings are renewed with new tread—has transitioned from an economical alternative to a mainstream sustainability imperative. Retreaded tires minimize raw material consumption, significantly lower energy use, and reduce carbon emissions associated with manufacturing new tires. Modern retreading technology offers performance, durability, and safety comparable to new tires, making them a preferred choice across logistics, mining, public transportation, and construction.

As global supply chains become more digitized and cost-sensitive, retreading technologies are transforming fleet management, enabling firms to improve uptime, reduce overall tire costs, and meet ESG goals. The synergy between sustainability and profitability is now driving a new era for the tire retreading industry.

To know the most attractive segments, click here for a free sample of the report: https://www.maximizemarketresearch.com/request-sample/81491/

Market Dynamics

1. Growth Driver: Rise in Global Vehicle Production

The expansion of the automotive sector—particularly commercial fleets—continues to be a major catalyst for the tire retreading market. Global vehicle production is expected to increase at over 6.8% CAGR, with developing economies leading the manufacturing acceleration.

This vehicle growth directly expands the market's core customer base. As fleet operators increasingly prioritize operational efficiency and sustainability, retreading becomes the preferred cost-effective alternative to expensive new tires.

2. Cost Efficiency: The Most Influential Market Force

Retreaded tires offer up to 50% cost savings compared to new tires. For heavy-duty commercial vehicles with high-frequency tire replacement cycles, these savings contribute significantly to bottom-line optimization. Premium-quality retreading materials, along with improved curing processes, ensure high mileage and reliable performance.

3. Opportunity: Fleet Modernization & Sustainability Commitments

Global fleets—spanning logistics, public transport, e-commerce, and industrial applications—are proactively adopting retreaded tires to reduce carbon footprint without compromising operational capabilities. Countries focusing on sustainable transportation practices, especially in Europe and Asia-Pacific, are creating fertile ground for market penetration.

4. Challenge: Perception & Quality Variability

While modern retreading technologies have improved substantially, misconceptions regarding reliability and safety still pose challenges in some markets. Additionally, quality inconsistencies across small-scale retreaders in developing countries impact customer confidence.

Segment Insights

By Production Method

- Pre-cure Retreading

This method dominates due to its cost benefits, flexibility in design, and higher retention of casing strength. It is widely used for commercial fleets. - Mold Cure Retreading

Known for superior aesthetics and improved tread bonding, mold cure remains important for high-performance applications.

By Vehicle Type

- Commercial Vehicles (Leading Segment)

The backbone of retreading demand globally. Rising transportation activities, e-commerce logistics, and high tire replacement frequency solidify this segment’s dominance. - Passenger Vehicles

Once considered negligible, this segment is gaining attention due to sustainability commitments and OEM interest in retread-compatible passenger tire design.

To know the most attractive segments, click here for a free sample of the report: https://www.maximizemarketresearch.com/request-sample/81491/

Regional Analysis

Asia Pacific – The Global Leader

The Asia Pacific region is expected to maintain its dominant share during 2025–2032.

- India emerges as a major hub where retreading saves hundreds of millions of liters of crude oil annually.

- Retreading is widely practiced in trucks and buses, significantly lowering operational costs in a price-sensitive transportation ecosystem.

- Strong economic growth, infrastructure expansion, and rising automotive ownership continue to drive demand.

China, Japan, South Korea, and Indonesia also contribute significantly due to established manufacturing bases and expanding logistics sectors.

Europe – A Mature & Sustainability-Driven Market

European nations are integrating retreaded tires into their sustainability frameworks:

- Public transport fleets in Germany and France have already implemented mandatory evaluation of retreaded tires.

- European consumers value sidewall aesthetics and premium-quality retread performance.

Stringent environmental regulations and carbon reduction goals reinforce market momentum.

North America

A well-established retreading culture, especially in the trucking industry, supports consistent growth in the United States and Canada. Investment in advanced retreading facilities continues to rise.

South America & MEA

Emerging markets such as Brazil, South Africa, and GCC countries show growing preference for retreading to reduce operational costs in mining, agriculture, and commercial transport.

Competitive Landscape

The market features a healthy blend of global giants and regional specialists. Companies are expanding production capability, adopting advanced curing technologies, and collaborating with OEMs to enhance casing compatibility.

Key Players

- Bridgestone Corp.

- Michelin SCA

- The Goodyear Tire & Rubber Co.

- Marangoni S.p.A

- Oliver Rubber Company

- Valley Tire Company

- TreadWright

- Kraiburg Austria GmbH & Co.KG

- Yokohama Rubber Co.

- JK Tyres

- MRF Tyres

- Rosler Tech Innovators

- Tyresoles

- Easters Treads

- Pilipinas Kai Rubber Corporation

Leading companies are also focusing on innovations in tread compound chemistry, automated inspection systems, and energy-efficient curing processes.

Future Outlook

With sustainability emerging as a non-negotiable imperative, tire retreading is entering a phase of accelerated modernization. Increasing adoption of radial tires, growth of multi-axle heavy-duty vehicles, and globally rising freight movement create strong long-term potential.

By 2032, the retreading industry is expected to become a cornerstone of sustainable mobility, redefining cost efficiency and environmental responsibility across the global transportation landscape.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness